- HOME

- Pneumatic Conveying System(P.C.S)

Pneumatic Conveying System(P.C.S) Products & Solution

SANKO AIR PLANT LTD. is our brother company and the top manufacture of P.C.S. They can supply suitable equipment and systems for customer's needs.

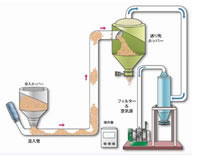

Pneumatic Conveying System(P.C.S) Flow Pattern

P.C.S. is the system which conveys powder/pellets through the conveying pipe by utilizing the flow of media gas such as air. There are mainly 4 kinds of Flow Pattern such as Plug Flow, Dune flow, Layer Flow and Suspension Flow, when we classify P.C.S by considering the Flow Pattern of

-

Plug Flow Dense Phase Conveying System

-

Dune Flow Dense Phase Conveying System

-

Layer Flow Dilute Phase

Conveying System -

Suspension (Dispersion) Flow Dilute Phase Conveying System

Equipment for P.C.S

To transfer materials using pneumatic power, rotary feeders and valves, various auto and manual valves, classifiers, separators, plumbing equipment, plumbing materials, and level meters are used, as well as other equipment for handling powder and granulated materials.

-

Rotary Feeder

-

PIATTO Feeder

-

Diverter Valve

-

Gate Valve

-

Double-barrel Pneumatic Classifier

-

EKOFLOW Pipes

-

Solid-Gas Separator

-

Pulse Type Level Sensor

-

PLUSU Loader

-

Others

Example of Plant Solutions